How a Timber Byproduct Is Changing 3D Concrete Printing

Sawdust From the Timber Industry Improves 3D Concrete Printing

What’s been happening: 3D concrete printing is on the rise across America

What’s new: wood composite is being used to make 3D concrete printing easier

How it affects forestry: Arkansas’s forestry industry may not be producing beams as often, but wood pulp will still play a big role in the home-building process

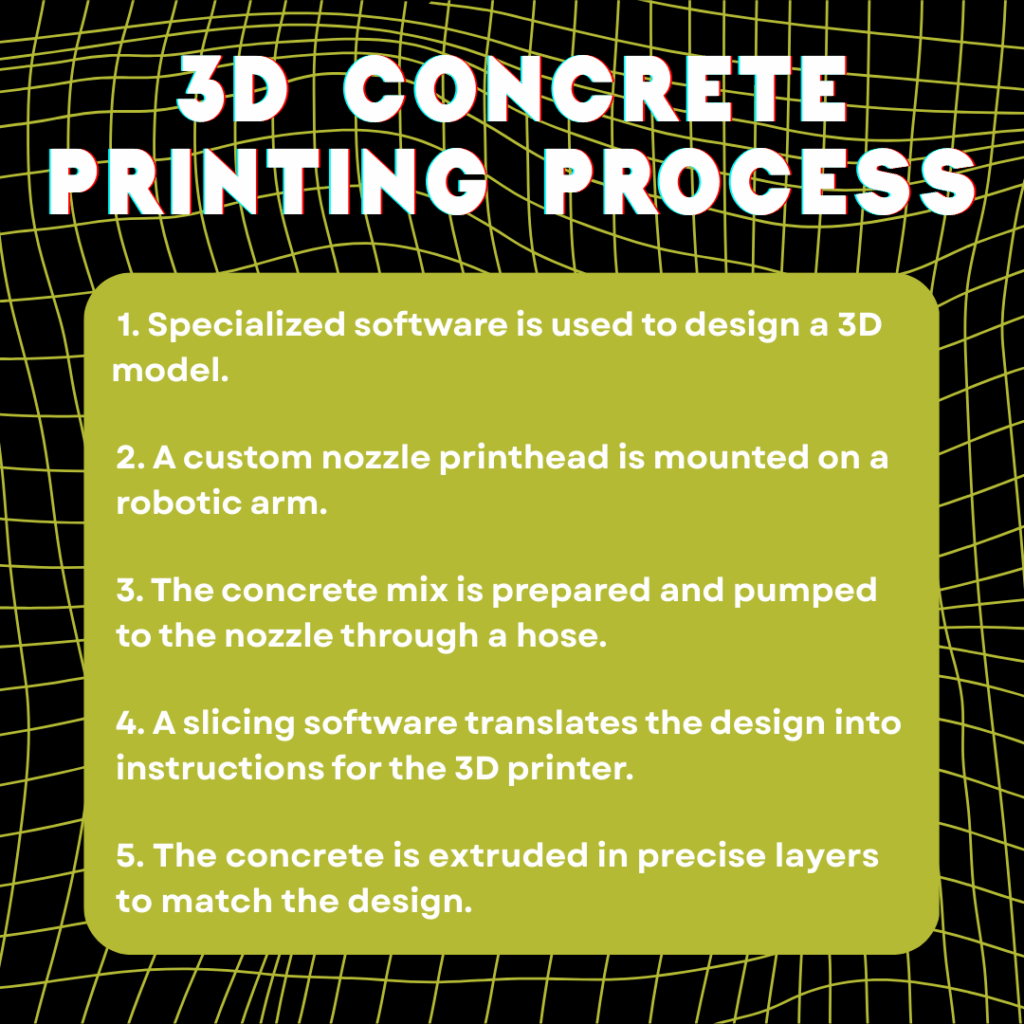

How does 3D concrete printing (3DCP) work?

3DCP isn’t all that new. In 2019, scientists Jay G. Sanjayan and Behzad Nematollahi suggested it had the potential to reduce—and even eliminate—the need for traditional timber frameworks in construction.

But what is new: 3DCP is preparing to sweep the nation. While expensive, these machines are becoming more common, and are likely to be offered by rental companies in short order.

Construction companies, and associated industries like timber, should be aware of the new opportunities and challenges 3DCP will offer.

The impact of 3D concrete printing

- Pro: 3DCP is more environmentally friendly than traditional wood construction because it produces fewer carbon emissions

- Con: it largely eliminates the timber industry

- Pro: 3DCP promises savings over time (especially for residential needs)

- Con: it has a high cost of entry

- Pro: 3DCP may reduce labor demand

- Con: it requires specific and skilled labor

- Pro: 3DCP exhibits promising strength initially

- Con: it’s susceptible to environmental degradation over time without a strengthening additive

Even with its associated cons, companies are moving forward with 3DCP. And many are turning to a waste product to help make 3DCP structures stronger: sawdust.

How wood fiber helps the process & makes it stronger

3D-printed concrete is strong, but not strong enough for long-term structures. So researchers from the University of Virginia School of Engineering and Applied Science came up with a solution: cellulose nanofibrils (CNF). And it can come from sawdust.

CNF has the potential to change the 3DCP process, strengthening the concrete and lowering its chances of cracking. It’s derived from waste wood pulp and helps concrete flow better without air bubbles (the biggest enemy to 3DCP structures).

Now, timber companies can market what’s typically a waste product as the holy grail for perfecting 3DCP and make it a major source of profit.

How Arkansas’s forestry industry can pivot and benefit with 3D Printing

3DCP isn’t immediately replacing all construction. But it’s important for lumber companies to start planning for the future now.

An article from France’s Universite de Lorraine concluded that “Wood waste is a huge stream for a new raw material…. there is high potential to create added value on wood waste.”

The timber industry can research up-and-coming 3DCP companies in Arkansas and focus on marketing their sawdust as a product to these companies by focusing on the following topics.

Stronger Concrete

The biggest draw for any 3DCP company is going to be how much wood byproducts can strengthen concrete.

We know it’s stronger, but how much stronger? Scientists concluded that “structural concrete can be manufactured with compressive strengths more than 20 MPa by replacing moderately 5–17% of the sand with sawdust.”

The University of Virginia study found that CNF-enhanced 3D-printed components stood up to pulling, bending and compression better than structures without CNF.

Another researcher found that “sawdust has the potential to make construction composites that are strong, absorb water, and have an elastic modulus.”

Carbon Sequestering

3DCP with wood fiber can add even more to the process through carbon sequestration: capturing and storing atmospheric carbon dioxide to reduce global pollution.

Some materials are more effective carbon sequestration materials than wood fiber, like biochar (a charcoal-like product created by heating biomass waste in a closed system). But wood fiber remains the best choice for carbon sequestration within concrete. It’s a natural product that doesn’t require any additional processing and isn’t ecotoxic to animal, plant, and microorganism life.

Other 3D Printing Uses for Sawdust & Concrete

A related solution, with different outcomes, is to use 3D printing techniques to create reusable concrete frameworks. Traditional concrete frameworks are difficult to recycle and end up contributing to waste.

So the BioMatters team at the University of Michigan came up with a way to 3D print sawdust into fully biodegradable and recyclable frameworks. This solution is still in its infancy, but it could revolutionize the concrete industry.

Takeaways

3DCP may become a more common choice in the future, but that doesn’t mean it’s the end of the timber industry.

Construction-focused 3D-printing, concrete, and timber are linked in more ways than one. The three together might even be the future of the construction industry. It’s important for the timber industry to recognize the power of sawdust and market it correctly to 3DCP companies.

Back to News

Subscribe and unlock cutting-edge equipment insights, trends and tips!

Subscribe