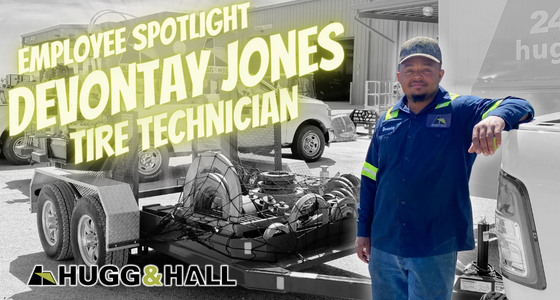

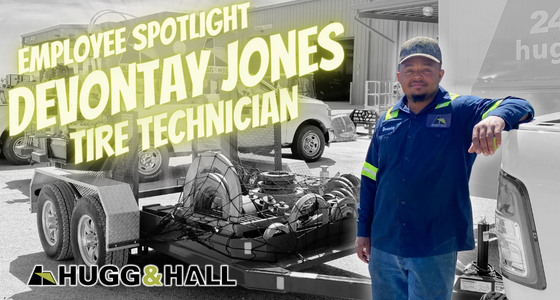

Employee Spotlight: DeVontay Jones

Meet DeVontay Jones, Tire Technician in Jonesboro, AR! DeVontay is Blytheville-born and grew up in...

Meet DeVontay Jones, Tire Technician in Jonesboro, AR! DeVontay is Blytheville-born and grew up in...

It's a simple idea: if you don't notice a problem with your equipment, you probably...

Meet Bruce Legg, Field Service Technician in Baton Rouge, LA! Bruce is an Army veteran...